2.Pressure Measurement-Manometers

Pressure Measurement-Manometers

There

are three types of Manometer which are explained below.

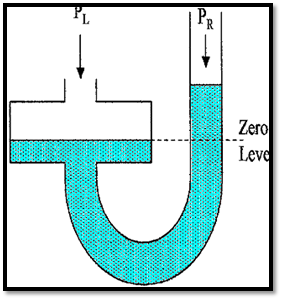

1) Open U-type Manometer: Manometers are

working on the principle of hydrostatic balancing.

Manometer

consists of a tube made of glass or other transparent material bent into the

shape of a U and with both ends left open.

The

force acting due to one liquid column on the same level or reference balances

the force acting due to another liquid column.

Highly

refined mineral seal oils of various densities are used in manometry for small

pressure differences.

For

higher pressure ranges mercury is used.

Water

is not generally used because it evaporates, leaves a lime deposit on the tube

wall

Since

the pressure acting on the liquid column it will form a meniscus, When the

meniscus is concave, the liquid column should be measured to the bottom of the

meniscus.

When

the meniscus is convex, the column should be measured to the top of the

meniscus.

Accuracy of Manometer:

Accuracy

is not affected by the shape or size of the tube.

Manometer

liquid used could affect the accuracy of the Measurement.

When

high specific- gravity liquids are used to measure extremely small pressures,

the following are important variables affect the accuracy:

Density.

Vapor

pressure.

Temperature.

2) Well type of Manometer: The left-hand limb

is replaced by a reservoir or well which has an area much larger than the area.

This operates on the principle of Pascal law.

Pressure to be measured is applied on the well side

and the reference pressure is applied on other side.

It is mainly used in laboratory and industrial

purposes.

3) Inclined Manometer: It has one limb that is inclined at an angle to the horizontal plane and a vertical limb that consists of a relatively large well. The sloping tube carries a scale adjacent to it. Inclined tube is used to achieve a longer scale than the ordinary U-tube manometer for the same pressure differentials.

Advantages of manometers with respect

to other inst.

1. Range is ± 30 inch of Hg.

2. Suitable for very low pressure Measurement.

3. The liquid is physically visual.

Disadvantages:

1. Bulky, size is big.

2. Glass tube is fragile so it is not

recommended for field use.

3. Accuracy of the instrument is depending up

to the temperature and other factors, which cannot maintain in field.

4. Mercury used in manometer make mercury

oxide, which is poisonous.

5. Manometers are not suitable for high

pressure Measurement and high temperature pressure Measurement.

6. Manometer’s liquid may react with the

process liquid.

Comments

Post a Comment