1.Introduction to PLC

Introduction

This knowledge is meant to supply you with basic information on PLC.

Control engineering has evolved over time. In the past humans were the main method for controlling a system. More recently electricity has been used for control and early electrical control was based on relays. These relays allow power to be switched on and off without a mechanical switch. It is common to use relays to make simple logical control decisions.

The development of low cost computer has brought the most recent revolution, the Programmable Logic Controller (PLC). The advent of the PLC began in the 1970s, and has become the most common choice for manufacturing controls. PLCs have been gaining popularity on the factory floor and will probably remain predominant for some time to come. Most of this is because of the advantages they offer.

- · Cost effective for controlling complex systems.

- ·

Flexible and can

be reapplied to control other systems quickly and easily.

- ·

Computational

abilities allow more sophisticated control.

- · Trouble shooting

aids make programming easier

- · Reduction in

downtime.

- · Reliable components make these likely to operate for years before failure.

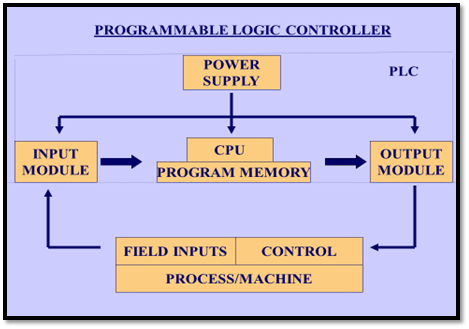

PLC

Programmable Logic Controllers (PLCs), also referred to as programmable controllers, are in the computer family. They are used in commercial and industrial applications. A PLC monitors inputs, makes decisions based on its program, and controls outputs to automate a process or machine. This knowledge is meant to supply you with basic information on the functions and configurations of PLCs.

Power Supply: It converts AC to

DC power and gives power to CPU, input module and output module.

CPU: The CPU is the brain of the PLC and

carries out programmed operations. These operations or outputs are executed

based on signals and data provided from connected inputs. The CPU is the

brain of the PLC and carries out programmed operations. These operations or

outputs are executed based on signals and data provided from connected inputs.

Input Module: Field inputs like

sensors, switches, push buttons are connected to inputs module. Input module

converts analog to digital and digital data is provided to CPU.

Output Module: Output modules convert signals from

the CPU into digital or analog values to control output devices like motors, valves,

actuators.

Programming: The

PLC manufacturer determines PLC development software. Allen Bradley, Siemens, Schneider

and GE each have their own software development platforms for programming their

PLC models. Once the platform is determined, the actual programming of the PLC

logic can be done in a different method is per IEC61131. The most common

methods of PLC programming include Ladder Logic, Function Block, structured

text, Sequential Function Chart and Instruction List.

Ladder Logic(LD)

Ladder Logic is a

graphical PLC programming language and is the most common method of

programming. Ladder Logic can be used to execute tasks such as sequencing, counting,

timing, data manipulation, and more. Ladder Logic is structured similarly to

relay logic; however, the physical switches and coils used in relay logic are

replaced by the PLC’s memory locations and I/O.

Structured Text(ST)

Structured text is a

text-based PLC programming language and is similar to Python, Visual Basic, or

C coding languages. Programming with structured text has multiple advantages,

such as the program requiring less space due to being text based instead of

graphic based.

Function Block(FBD)

Function block PLC

programs are represented in the form of graphical blocks. Signals or data flow

into the function block from inputs connected to the PLC.

Sequentially

Function Chart(SFS)

Sequentially function chart(SFS)

contains 3 basic elements to organize the program. Those are steps transition

and actions.

Instruction List(IL)

Instruction List (IL) is a list of instructions, similar to assembly

language, that are run in order. It is low level programming language.

Further:https://automation-4-u.blogspot.com/2023/04/2programming-of-plc.html

Comments

Post a Comment